Printing profiles make working with a 3D printer much easier. Instead of laboriously working out the necessary parameters for your material and investing a lot of time and money, you can simply get started with printing profiles. You only have to buy the appropriate filament and you can choose from up to 11 profiles per material, color and nozzle size.

The current cura configuration contains over 3000 tuned printing profiles for the Weedo X40 / X40 PRO!

ATTENTION:

The print profiles cannot be used with the hacked Cura version of Weedo, because the printer definition at Weedo runs on a basic printer profile and the settings in the material profiles are not interpreted correctly. This leads to incorrect temperature information. The through profiles only work correctly with the X40 community Weedo X40 printer definition (integrated in the original Ultimaker Cura from Cura 4.12)

The X40 community has started a project to create these profiles. Complex and many printing tests have to be carried out for this. The calibration in the Cura start code ensures that everyone gets the same print result if the printer corresponds to the original Weedo status.

The necessary material tests were carried out with material freshly taken from the vacuum packaging. For good print quality, please ensure that your filament is stored correctly, otherwise printing problems can quickly arise.

Since all properties can be reproduced equally well with an FDM print, so-called intentions were introduced. As with Ultimaker, there are the following intentions:

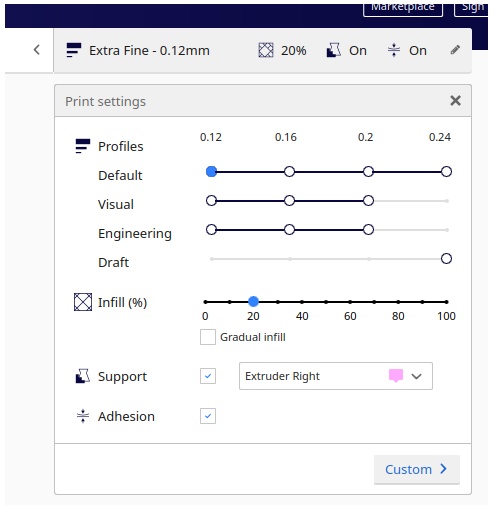

Printing profiles

From Release 05 or newer

| Layer height | Profile description | Nozzle 0,4mm | Nozzle 0,6mm | Nozzle 0,8mm |

| 0,12mm | Extra Fine | X | ||

| 0,16mm | Fine | X | X | |

| 0,20mm | Normal | X | X | X |

| 0,24mm | Draft | X | X | X |

| 0,28mm | Coarse | X | X | |

| 0,32mm | Extra coarse | X |

The generic profiles are supported by both nozzle sizes. Some materials can only be printed with the 0.6mm nozzle, because the 0.4mm is clogged or unsuitable.

Attention

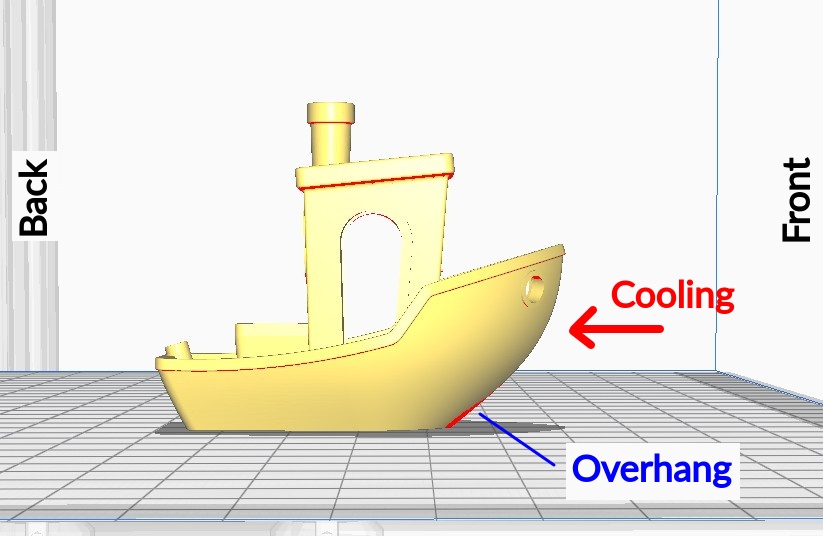

With the Extra Fine Profiles it can happen with some materials that the print is not perfect because the cooling from the Weedo X40 is not good enough. I therefore recommend using a maximum of 0.16mm layer height (Fine profile). For components with overhangs, you should align the overhang to the front so that the fan can blow the overhang as well as possible.

With many materials, the deficiencies can be eliminated by installing the X40 Community Cooling System.

- Default (0,4mm Nozzle)

With the default profile, you get a good surface and component strength with an average printing duration. A wall thickness of 0.8mm (two layers) is used for all default profiles. You can choose from many different layer heights.

Profile Layer height Printing speed Benchy printing time Default Extra Fine 0,12mm 30mm/s 4 hours 30 minutes Default Fine 0,16mm 40mm/s 3 hours 01 minutes Default Normal 0,20mm 50mm/s 2 hours 16 minutes Default Draft 0,24mm 60mm/s 1 hours 40 minutes - Visual (0,4mm Nozzle)

The main feature of the visual profiles is the perfect look. A wall thickness of 1.2mm (three layers) is used for this. You can choose from three different layer heights. The Z-seam is hidden as much as possible. With Cura 4.9 you can also check it and, if necessary, change it by adjusting the parameters.

Profile Layer height Printing speed Benchy printing time Visual Extra Fine 0,12mm 30mm/s 5 hours 02 minutes Visual Fine 0,16mm 40mm/s 3 hours 26 minutes Visual Normal 0,20mm 50mm/s 2 hours 31 minutes

The Extra Fine profiles can have rough surfaces on overhangs. It is then better to use the Fine profile. - Engineering (0,4mm Nozzle)

The main feature of the engineering profile is strength and dimensional accuracy. This is achieved with a wall thickness of 1.2mm, a standard fill density of 30%, printing the outer wall in front of the inner wall and activating acceleration with jerk. In addition, the Z-seam is placed randomly so that there is no weak point. You may have to accept visual losses with the engineering profile.

Profile Layer height Printing speed Benchy printing time Engineering Extra Fine 0,12mm 30mm/s 3 hours 08 minutes Engineering Fine 0,16mm 40mm/s 2 hours 23 minutes Engineering Normal 0,20mm 50mm/s 1 hours 55 minutes

The Extra Fine profiles can have rough surfaces on overhangs. It is then better to use the Fine profile. - Draft (0,4mm Nozzle)

The draft profile is about getting a model of acceptable quality as quickly as possible.

Profile Layer height Printing speed Benchy printing time Draft Draft 0,24mm 70mm/s 1 hours 35 minutes

Supported Materials (2022-11-04)

- You can find the results of our large material test here.

- Why is there no ABS in the support material list?

ABS is not that easy to print. From experience, there is also a delay in ABS, which should be suitable for open printers, or the components become detached from the printing platform. The printing bed temperature required for ABS is just reached with some ABS materials or with many ABS it is higher than the printer can produce. In addition, toxic gases are produced during printing. With an open printer, you should therefore have a well-ventilated and lockable room. Together with the warping problems, there are often many misprints.

This is not in line with our philosophy of producing the most perfect print results possible and as little waste as possible!

There are now good replacements for ABS material, such as Impact PLA, PolyMaker PolyMax PLA, PCTG, GreenTEC Pro or ASA materials. - Why is there no Carbon fiber reinforced material listed?

Carbon fiber reinforced materials are very stiff, but have two problems. The machining post-processing results in very fine stiffness that goes into the lungs and can make you seriously ill. So you have to wear an appropriate protective mask. The second problem is poor environmental protection. Carbon fibers are harmful to the environment and, in large quantities, can even damage waste incineration plants.

| Manufacturer |

Filament | Color | Nozzle 0,4mm | Nozzle 0,6mm | Status | Coolingsystem |

| add:north | E-PLA | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | X-PLA | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | Textura™ Flare | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | OBC Polyethylene | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | PLA Wood | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | PETG | All | Works | Done | Only for X40 Pro Configuration | |

| add:north | Adura | All | Works | Done | Only for X40 Pro Configuration | |

| colorFabb | PLA/PHA | All | Works | Done | Only for X40 Pro Configuration (Extra Profiles) | |

| colorFabb | PHA | All | Works | Done | Only for X40 Pro Configuration (Extra Profiles) | |

| colorFabb | NGEN | All | Works | Done | Only for X40 Pro Configuration (Extra Profiles) | |

| colorFabb | NGEN-FLEX | All | b. Doesn't work | ??? | in progress | |

| colorFabb | PA Neta | All | in planning | |||

| 3DJAKE | ecoPLA | All | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| 3DJAKE | ecoPLA Matt | All | Works | Done | Only testet with X40 Community Coolingsystem | |

| 3DJAKE | ecoPLA Tough | All | Works | Done | Only testet with X40 Community Coolingsystem | |

| 3DJAKE | PETG | All | Works | Done | Only testet with X40 Community Coolingsystem | |

| 3DJAKE | PVA | - | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| 3DJAKE | PCTG | All | in planning | |||

| Extrudr | GreenTEC Pro | All | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Extrudr | GreenTEC | All | Works | Done | Weedo X40 PRO with X40 Community Coolingsystem | |

| Extrudr | BioFusion | All | Limited | Done | Works only with X40 Community Coolingsystem | |

| Extrudr | GlowEX PETG | All | b. Doesn't work | Works | Done |

Only testet with X40 Community Coolingsystem |

| Extrudr | TPU medium | All | Works | Done |

Only testet with X40 Community Coolingsystem | |

| Fiberlogy | BVOH | - | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Fiberlogy | Easy PLA | All | a. Doesn't work | Works | Done | X40 Community Coolingsystem |

| Fiberlogy | FiberSilk | All | Works | Done |

Works only with X40 Community Coolingsystem | |

| Fiberlogy | Impact PLA | All | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Fiberlogy | Fiberwood | All | b. Doesn't work | c. Works | Done |

Only testet with X40 Community Coolingsystem |

| Fiberlogy | Easy PET-G | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Fiberlogy | PCTG | All | d. Works | Done |

Only tested with X40 Community Coolingsystem | |

| Fiberlogy | PLA Minera | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Fiberlogy | FiberSatin | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Fiberlogy | ASA | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Fiberlogy | PP | All | Works | e. Doesn't work | Done | Only for X40 Pro Configuration |

| Fiberlogy | CPE-HT | All | e. Doesn't work | e. Doesn't work | Done | Only tested with X40 Community Coolingsystem |

| Fiberlogy | HIPS | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Filamentum | NonOilen | Nature | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Filamentum | CPE HG 100 | All | Works | Done | Only for X40 Pro Configuration | |

| Igus | I150-PF | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Material4Print | PLA | All | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Material4Print | PET-G | All | Works | Done |

Weedo X40 or X40 Community Coolingsystem | |

| Material4Print | ASA | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Material4Print | PMMA | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyDissove S1 | - | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Polymaker | PolyDissove S2 | - | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Polymaker | PolyTerra PLA | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyMax PLA | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyFlex TPU95 | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyLite PLA | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyLite PETG | All | Works | Done | Only tested with X40 Community Coolingsystem | |

| Polymaker | PolyMax PC | All | in planning | |||

| Prusament | PVB | All | a. Doesn't work | Works | Done |

Only testet with X40 Community Coolingsystem |

| Tarfuse | ENVI 1 | Nature | Works | Done | Only tested with X40 Community Coolingsystem | |

| Verbatime | PLA | All | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Verbatime | BVOH | - | Works | Done | Weedo X40 or X40 Community Coolingsystem | |

| Verbatime | PET-G | All | Works | Done |

Weedo X40 or X40 Community Coolingsystem | |

| Verbatime | DuraBio | All | Works | Done |

Only tested with X40 Community Coolingsystem | |

| FormFutura | ApolloX ASA | All | Works | Done | Only tested with X40 Community Coolingsystem |

Annotation:

- At the printing temperature recommended by the manufacturer, the viscosity of the melt is so high that the filament cannot be reliably transported by the extruder (jerky slipping).

- To avoid clogging of the nozzle, the manufacturer recommends a nozzle diameter of at least 0.5mm.

- Printing is possible, but the parts are not ready to use. The parts have to be reworked to remove stringing, pimples or the like.

- To avoid the problem with the heating failed, please use the preheating function and only start printing shortly before the temperature is reached.

- The print object does not adhere to the print bed

Heating failed:

With some print profiles, the error "Heating failed" can occur. You can avoid the error by preheating the bed to approximately the desired temperature with the preheating function and only starting printing with a hot print bed. If the error occurs when preheating the nozzle and heating bed, then there may be a defect.